At BARRIER SOFTWARE Services, we take immense pride in our team of highly qualified professionals, complemented by a motivated workforce whose extensive expertise has been meticulously honed through international employment experiences and active participation in a variety of multinational projects. We embrace a philosophy that encourages us to view every project as an invaluable opportunity to establish and nurture long-term relationships with our clients. This commitment not only enhances our service delivery but also reinforces our role as a trusted partner in your journey toward progress and success. With BARRIER SOFTWARE Services, you can be assured that you have a dedicated ally by your side, ready to support you at every step of the way.

BARRIER SOFTWARE Services is deeply committed to sourcing and delivering a highly effective and cost-efficient range of products and services tailored to address the diverse needs of the industrial market. With expertise across various specialized areas, we ensure that we meet the unique requirements of our clients while upholding high standards of quality and performance. We take pride in our ability to stay ahead of industry trends and innovations, enabling us to provide solutions that not only meet current demands but also prepare our clients for future challenges. Our focus includes the following key areas:

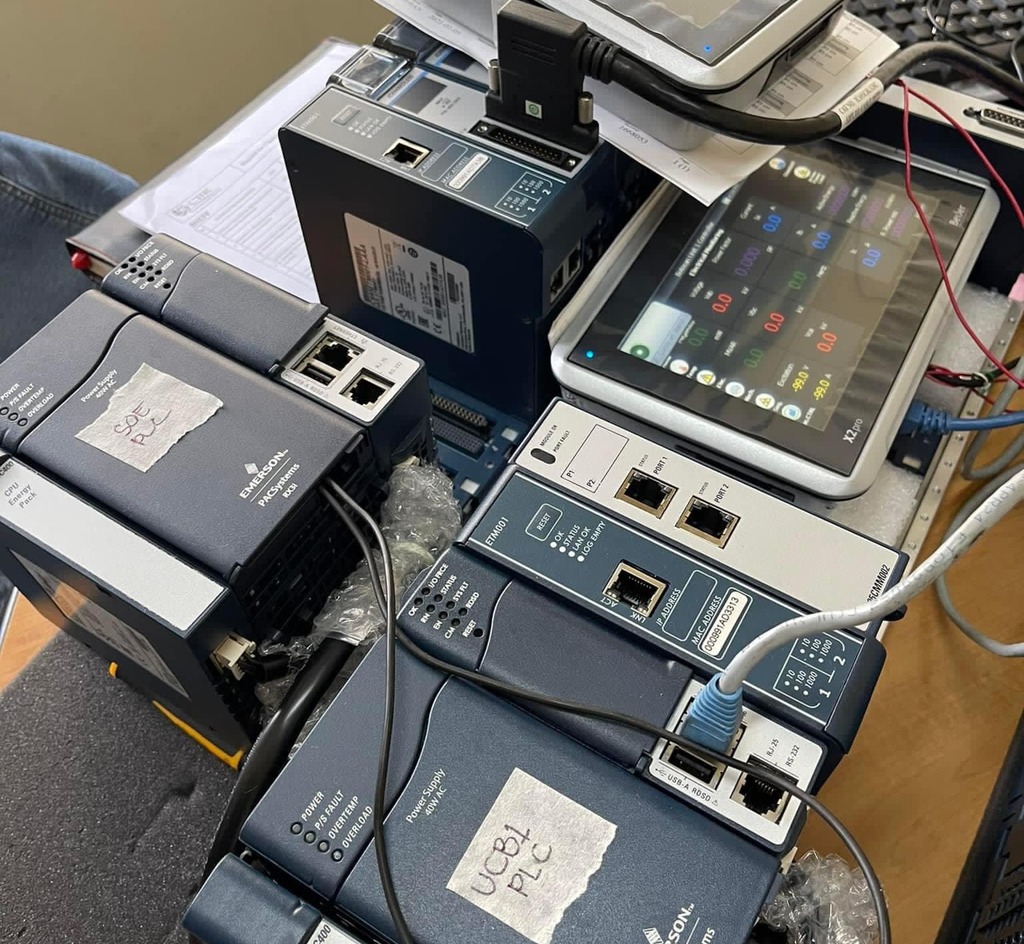

Upgrade of Stacker Reclaimer Units 1 and 2: Implementation of a Redundant Controller CPU Upgrade to CPE315 for Enhanced Performance and Reliability in the Pacsystem.

We have successfully installed a cutting-edge new crusher house, featuring an advanced Remote Control Panel that is powered by the sophisticated Emerson PACSystems controller.

We are pleased to announce the upgrade of the main control CPU in our Electro Chlorination Plant to the state-of-the-art CPE315 model. This enhancement will greatly enhance system efficiency and reliability, ensuring optimal performance in our chlorination processes.

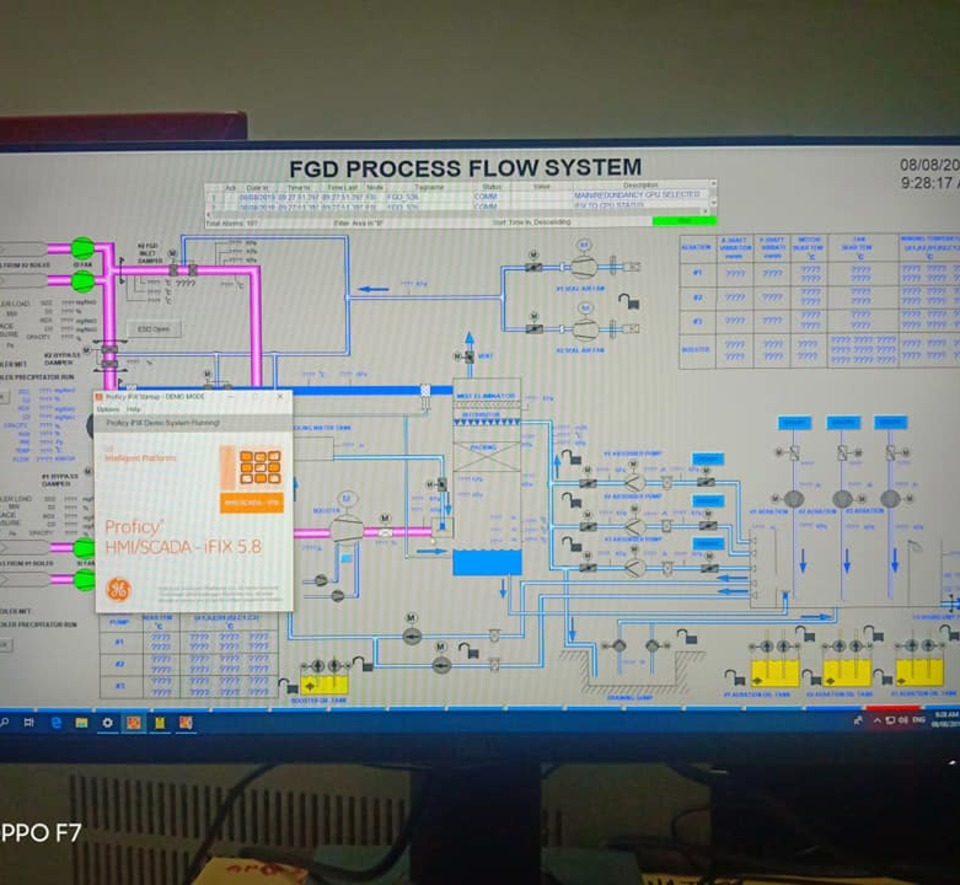

We specialize in debugging the Flue Gas Desulfurization (FGD) Flue Pacsystem Control Program. Our expertise enhances air pollution control systems for peak efficiency while maintaining strict environmental standards. Our dedicated team addresses issues in these complex systems, contributing to cleaner air and a healthier environment.

Material Handling Solutions: Upgrade Your Control Systems.

Enhance your material handling operations with a control system upgrade from the outdated Ge Rx7i Controller to the advanced Emerson Pacsystem Rx3i. This transition boosts performance and reliability while incorporating the latest features and innovations, keeping your operations competitive and efficient in a fast-changing industry.

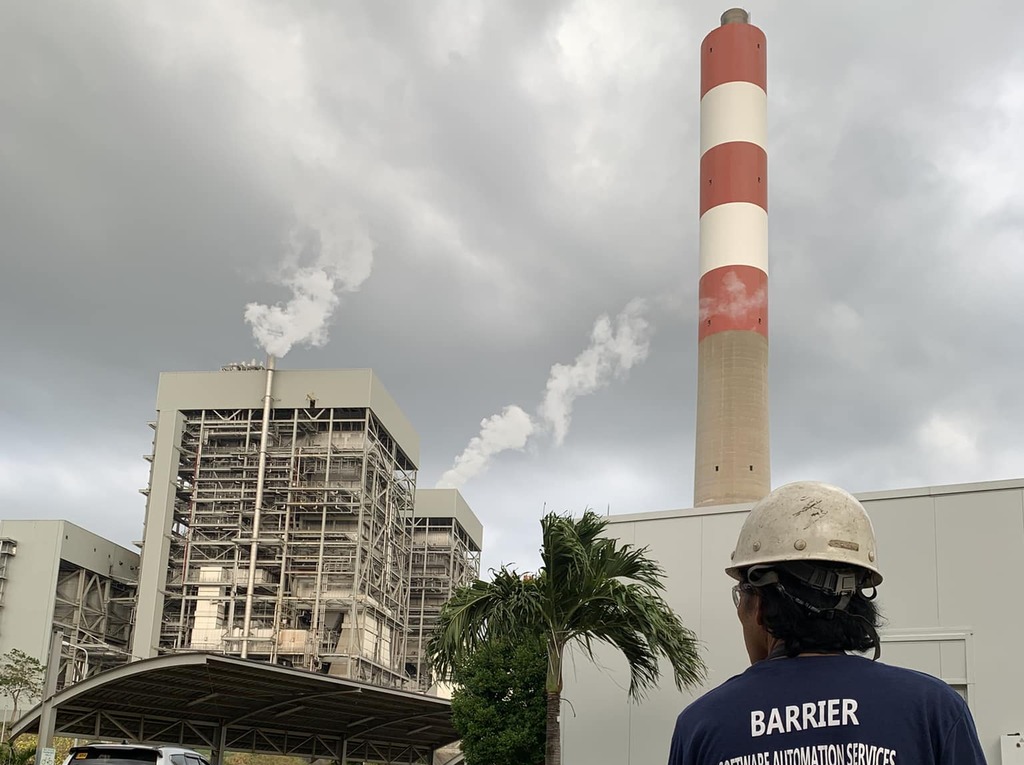

Restoration of PLC Program for SIL3 Turbine Control at Semirara Power Plant.

This project focuses on restoring and enhancing the PLC program for the SIL3 Turbine Control Protection system at Semirara Coal-Fired Power Plant. It's essential for ensuring the safety and efficiency of turbine operations, which are critical for power generation.

From our advanced convention control panel, we are pleased to announce the upgrade of the fire pump system to incorporate state-of-the-art PLC (Programmable Logic Controller) technology along with an intuitive HMI (Human-Machine Interface) control system. This enhancement not only improves operational efficiency but also ensures greater reliability and ease of monitoring for fire safety systems.

We have successfully installed a new Proxy Data Manager server utilizing the Dell PowerEdge system. This advanced setup is designed to efficiently collect and manage data from the BOPs Server. The integration employs the OPC UA Server, which communicates seamlessly with the Kepware OPC UA Client. This configuration enhances data exchange and operational efficiency, ensuring reliable access to critical data for our ongoing projects. Collaboration with OBX system integrator

The Emerson Pacsystem Project optimizes the BOP Controller at GMEC Coal-Fired Power Plant, enhancing efficiency and reliability. By integrating advanced technology, it improves operations and supports the facility's energy production goals sustainably.

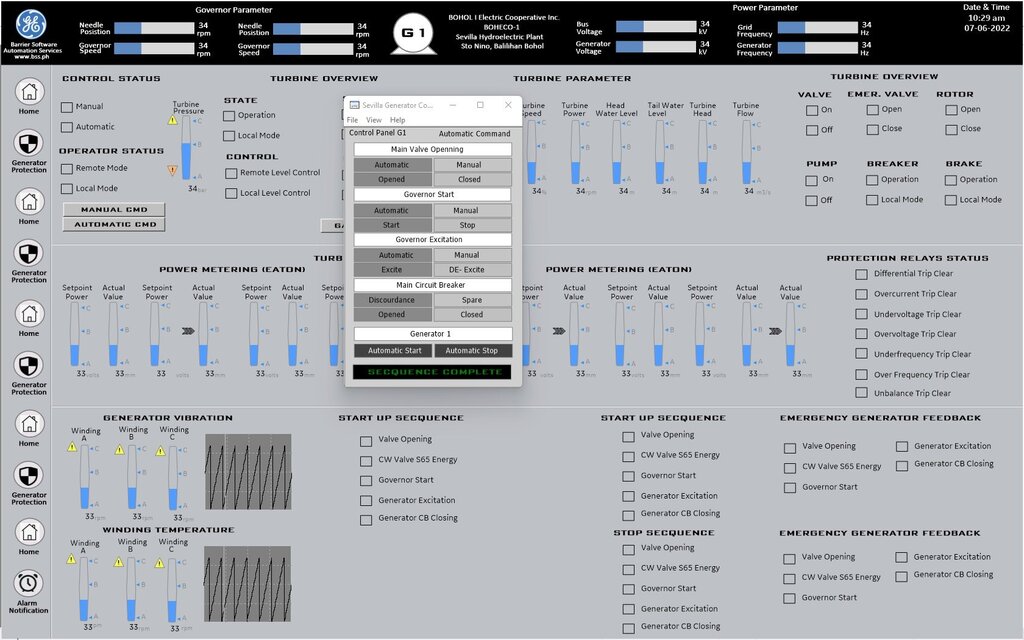

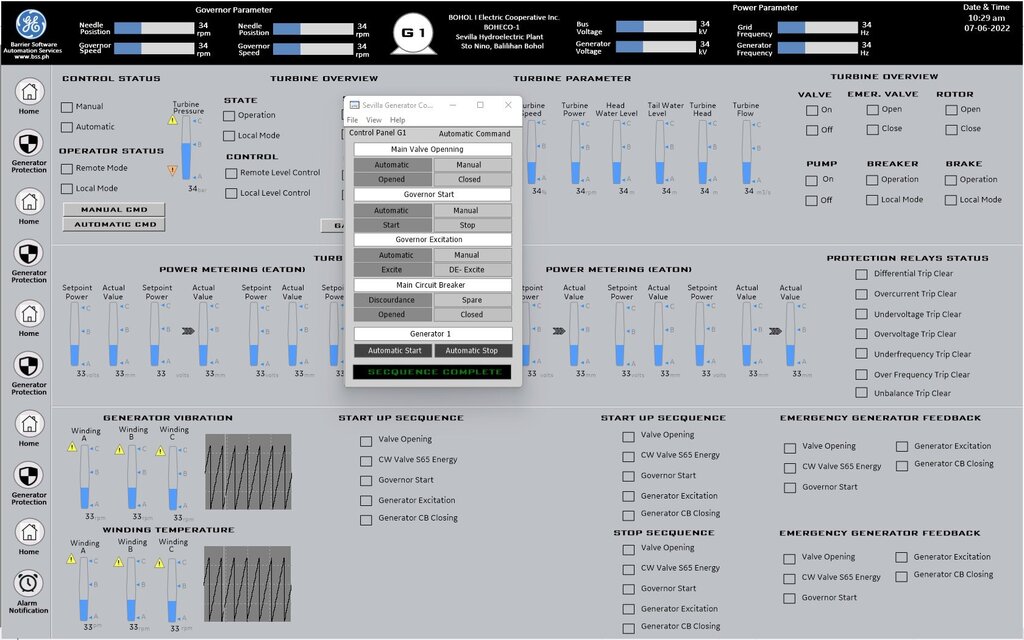

Turbine Control Tuning optimizes turbine system performance and efficiency by adjusting control parameters for maximum potential. This fine-tuning enhances stability, responsiveness, and energy output while reducing costs. It also extends equipment lifespan and requires a deep understanding of turbine dynamics. Whether for wind, gas, or hydro turbines, proper tuning is vital for peak performance and reliability. Our experts use advanced techniques to ensure your turbine systems operate smoothly and efficiently.

Turbine Control Commissioning ALSPA: Ensuring Optimal Performance

At Advanced Systems and Process Automation (ASPA), our Turbine Control Commissioning process is essential for integrating turbine systems efficiently. We provide accurate calibration, testing, and optimization to ensure peak performance.

Our experts assess all components for reliability and safety, enhancing performance and extending system lifespan while ensuring compliance with industry standards. Trust ASPA for a seamless commissioning process that promotes sustainable energy solutions and operational success.

GE ASLPA Training

Welcome to the GE ASLPA Training program, designed to enhance your skills and knowledge. Our sessions cater to all levels, from beginners to experienced professionals, providing valuable insights into our advanced systems and technologies.

Participants will engage in hands-on activities, expert-led workshops, and interactive discussions in a supportive environment. Join us to develop your competencies and stay ahead in the industry with our specialized training programs.

Emerson pacsystem control

Emerson pacsystem control

cimplicity

ifix

ix developer biejer

cimplicity